Thanks to the stereotypical depictions of robots in the mainstream media and works of science fiction, most people have an idea of robots as figures with human-like features and attributes. However, this is just one type of many robots that are already in existence today. Any automated device that approximates human motion and tasks can be considered a robot. In short, it does not necessarily need to possess a human-like exterior.

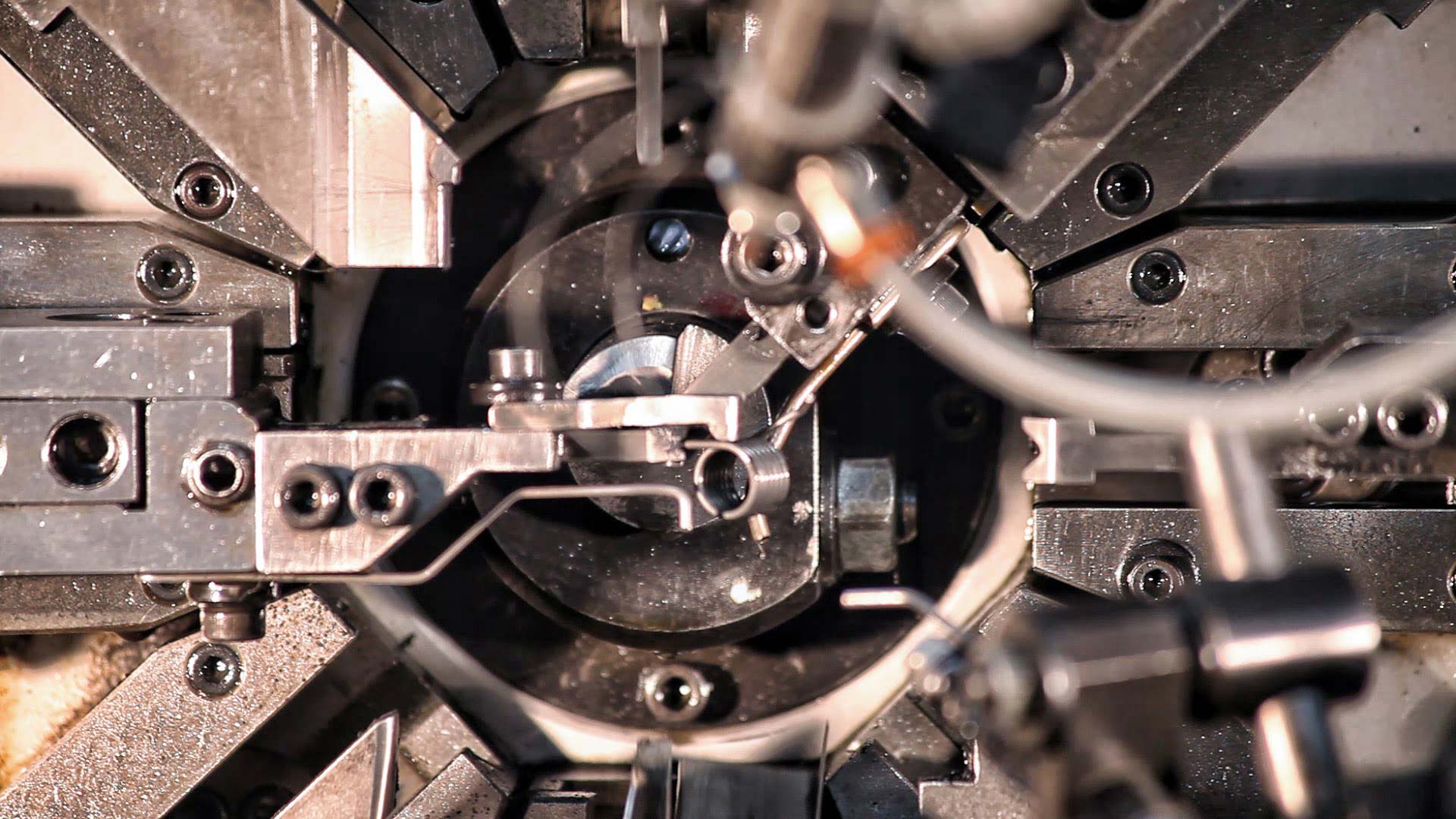

That being said, robots are very much present in many aspects of modern life today, especially in manufacturing. These manufacturing robots are typically powered by equally high-tech components and parts such as precision motion control systems, actuators, and brushless DC motors that provide a wide range of operability. This aspect of robotics is vital in order to accurately approximate human motion and achieve the tasks at hand.

Consider that in the traditional manufacturing set-up, human workers are usually in an assembly line and perform a certain sequence of manual tasks. Such a process is labor-intensive and time-consuming. Production timetables also have to be reviewed and readjusted from time to time to factor in the availability of raw materials, absences in the labor force, and other factors.

With the utilization of robots in manufacturing, the way that goods and products are manufactured has definitely changed for the better and has spelled increased profitability for many business owners. Here are just some of the benefits they have brought about:

Faster time-to-market. Automated machines such as robots have faster turnaround times in terms of tasks and procedures since they can virtually work round the clock. This enables products to be completed and delivered at a faster rate, enhancing the competitiveness of manufacturers in the market.

Improved product quality. Robots are able to perform repetitive tasks with less or virtually no error, compared to humans who may falter due to physical strain. Thus, the finished product tends to be more consistent in quality and more faithful to the intended output. Robots can also perform the important final task of quality control checks.

Minimized occupational hazard. Sometimes, manufacturing processes need to be carried out in harsh or unsafe environments, or they may involve the handling of dangerous components or substances. Thanks to robots that can perform these tasks, however, human workers are now safer than ever from occupational risks.

Overall lower manufacturing costs. All these benefits ultimately mean lower operational and production costs for companies due to less labor, less rework less wasted raw materials, and other factors that contribute to economies of scale. In turn, these savings also contribute to healthier margins and higher profits.

Investing in automated manufacturing solutions. Automating manufacturing processes with the help of high-tech robots may be costly in the beginning, but it is definitely worth the investment in the long run. With the sophistication of robotic technologies today, efficiency keeps improving and many other features and functionalities are being developed.

Once automated manufacturing systems are in place, robots and other automated machinery can easily be renewed with the latest software and other product updates that come along. This also helps keep businesses competitive and abreast of manufacturing best practices.

It is therefore important for business owners to partner with robotics and robotic components providers that offer high-quality, reliable, and cost-efficient equipment. After-sales service is also important for maintaining smooth manufacturing operations.